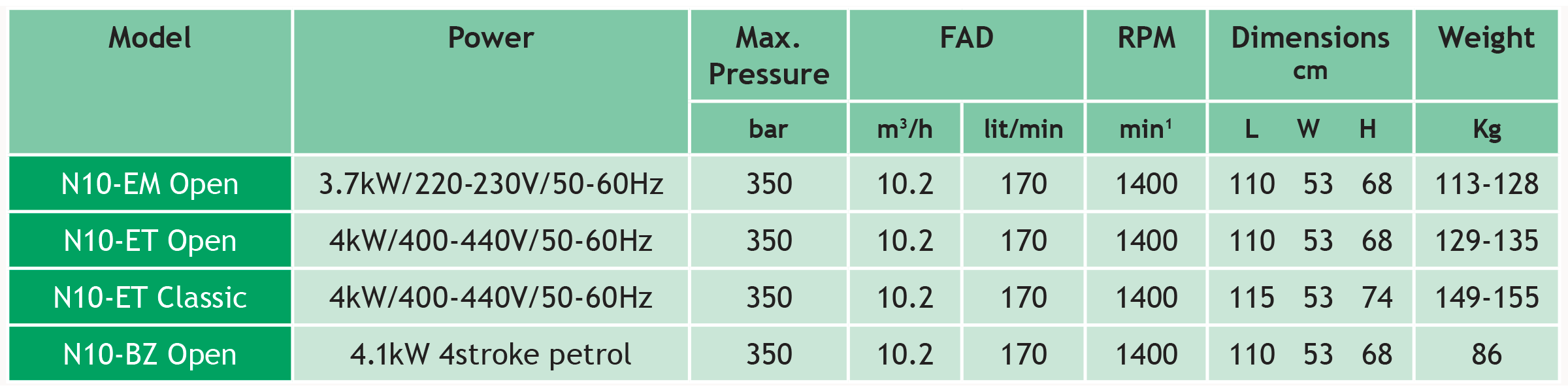

Technical Data

Design Specifications

|

N10-EM Open |

N10-ET Open |

N10-ET Classic |

N10-BZ Open |

|

|

Micronic Air Inlet Filter |

● |

● |

● |

● |

|

Condensate Separator after 2nd Stage |

● |

● |

● |

● |

|

Large Stainless Steel Intercoolers – Aftercooler in all stages |

● |

● |

● |

● |

|

Combined BA Filter including Coalescing Pre-filter (0.5mg/m3 oil residual) and 2 x BA cartridges (AC/MS + HP option), with the supply of absolutely clean air exceeding by far the requirements of EN 12021 |

● |

● |

● |

● |

|

Safety Bleed valve in case of BA Cartridge absence |

◆ |

◆ |

◆ |

◆ |

|

Pressure maintaining & non-return valve for extended filtration |

● |

● |

● |

● |

|

Start/Stop switch |

● |

● |

● |

■ |

|

Motor thermal overload protection |

● |

● |

● |

■ |

|

Manual Condensate Drains |

● |

● |

● |

● |

|

Kevlar filling hose (1.2m) with stainless steel fittings and DIN/INT'L connector |

● |

● |

● |

● |

|

Handles for easy lifting |

● |

● |

■ |

● |

|

Safety Valves in all stages |

● |

● |

● |

● |

|

Final Stage manometer |

● |

● |

● |

● |

|

Automatic belt tensioning system |

● |

● |

● |

● |

|

Electric hourmeter |

● |

● |

● |

■ |

|

Vibration hourmeter / service timer (Running hours, BA filter / oil service hours) |

◆ |

◆ |

◆ |

● |

|

Automatic stop system |

◆ |

◆ |

◆ |

◆ |

|

Automatic start system |

◆ |

◆ |

◆ |

■ |

|

Automatic condensate drains with manual backups + Condensate collecting tank. |

◆ |

◆ |

◆ |

■ |

|

Dual pressure filling facility, allowing 225/330bar alternative filling |

◆ |

◆ |

◆ |

◆ |

|

Star/Delta starter system |

■ |

■ |

◆ |

■ |

|

Low oil level monitoring / alarm / shutdown |

■ |

■ |

◆ |

■ |

|

High temperature monitoring / alarm / shutdown |

■ |

■ |

◆ |

■ |

|

24VAC secondary voltage providing safety during routine operation |

■ |

■ |

◆ |

■ |

|

Emergency Stop button |

■ |

■ |

● |

■ |

|

Main Switch |

■ |

■ |

● |

■ |

|

Remote start/stop |

■ |

■ |

◆ |

■ |

|

Condensate separator after 3rd (final) stage |

◆ |

◆ |

◆ |

◆ |

|

Interstage manometers |

● |

● |

● |

● |

|

1.5m air inlet hose with particle strainer |

◆ |

◆ |

◆ |

● |

|

Special voltage/frequency 3x230V/60Hz * 460-480V/60Hz |

■ |

■ |

◆ |

■ |