“All Typhoon Tropical models are designed for high ambient temperatures (50o C) & increased humidity environment”

Technical Data

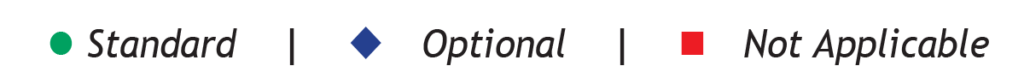

Design Specifications

|

Classic 18E TROPICAL |

Classic 18D TROPICAL |

|

|

Star/Delta starter system |

● |

■ |

|

Electric Starter/Battery fitted |

■ |

● |

|

Advanced digital controller providing operation (running hrs, filling pressure, operating temperature), control (start/stop/reset/menu button) & service (service hrs-alarm, records of the last 15 malfunctions) data |

◆ |

■ |

|

Oil pump lubrication |

◆ |

◆ |

|

Lifting eyebolts for easier transportation |

● |

● |

|

Galvanized & powder Coated frame and covers |

● |

● |

|

Electric Hourmeter |

● |

■ |

|

Vibration hourmeter/service timer (Running hours, BA filter/oil service hours) |

◆ |

● |

|

Voltage Failure & Phase Rotation Safety Device |

● |

■ |

|

Start/Stop switch |

● |

● |

|

Motor thermal overload protection |

● |

■ |

|

Automatic stop system |

● |

● |

|

Automatic start system |

◆ |

■ |

|

Automatic condensate drains with manual backups |

● |

● |

|

24V secondary voltage providing safety during routine operation |

● |

■ |

|

Emergency Stop button |

● |

■ |

|

Micronic air inlet filter |

● |

● |

|

Pressure maintaining & non return valve for extended filtration |

● |

● |

|

Condensate Separators in all stages |

● |

● |

|

Combined BA Filter including Coalescing Pre-filter (0.5 mg/m3 oil residual) and BA cartridge |

● |

● |

|

Safety Bleed valve in case of BA Cartridge absence |

◆ |

◆ |

|

Large Stainless Steel Intercoolers – Aftercooler |

● |

● |

|

Safety Valves in all stages |

● |

● |

|

Interstage pressure sensors providing emergency shutdown in case of overpressure |

◆ |

■ |

|

2 Kevlar filling hoses (1.2m each) with stainless steel fittings and DIN/INT'L connectors |

● |

● |

|

Lever operated on/off filling valves with automatic ventilation |

● |

● |

|

Dual pressure filling facility, allowing 225/330 bar simultaneous filling via pressure regulator |

◆ |

◆ |

|

Remote Start/Stop – Remote Load/Unload |

◆ |

■ |

|

Interstage/Final stage Manometers |

● |

● |

|

High Temperature monitoring / alarm / shutdown |

● |

● |

|

Low Oil level monitoring / alarm / shutdown |

● |

● |

|

Carbon Monoxide (CO) monitoring / alarm / shutdown system |

◆ |

◆ |

|

Hydrogen Sulfide (H2S) monitoring / alarm / shutdown system |

◆ |

◆ |

|

Humidity (H2O) monitoring / alarm / shutdown system |

◆ |

◆ |

|

Carbon Dioxide (CO2) monitoring / alarm / shutdown system |

◆ |

◆ |

|

OIL-VOC monitoring / alarm / shutdown system |

◆ |

◆ |

|

Condensate collecting tank |

● |

● |

|

Special Voltage/Frequency: 230V/50Hz-60Hz * 3x230V/60Hz * 460-480V/60Hz |

◆ |

■ |

|

Automatic belt tensioning system |

● |

● |

|

1.5m air inlet hose with particle strainer |

◆ |

● |